U-STUCCO™ FRX

Ultra Light-Weight Portland Cement Based Fire-Proofing

Highest durability and toughness on the market

Hydrocarbon Fire rated up to 4 hours

Jet Fire rated up to 2 hours

Cellulosic fire rated up to 4 hours

Cryogenic protection against LNG spills and immersion exposures

Resistant to 3 bar blast overpressure

High Resistance to wide range of climates

Ultra Lightweight – one-sixth the weight of concrete for equal fire protectio

Easy application by spray or trowel

No special priming required

Asbestos-free – complies with EPA and OSHA regulations

PRODUCT HIGHLIGHTS

Combined thermal and fire protection.Easily applied by spray or trowel.Class I rated, Nonflammable and Noncombustible.Asbestos-free. Complies with EPA and OSHA regulations.High crack and corrosion resistant.Ready-to-use powder mix product. Add water and apply.Provides superior water-resistance and moisture protection compared to alternative products.Can be applied in a single pass of up to 1” (or less) to nearly any substrate, including plywood, OSB, CMU blocks, concrete, metal, AAC, EPS, XPS and ICF systems.Covers “thermal breaks” in wall assemblies and significantly enhance any structure’s insulation performance and energy efficiency.

MATERIAL STANDARDS

Cement : ASTM C150 Light Weight Aggregate : ASTM C330 / C332 FIRE STANDARDS

United States : ASTM E 136 / ASTM E84 Australia : AS 1530.1 / AS 5113PRODUCT DESCRIPTION

U-STUCCO™ FRX provides both hydrocarbon and cellulosic fire protection for structural steel and can also be used to upgrade the fire resistance of existing concrete and ICF systems. U-STUCCO™ FRX provides 1 to 4 hour fire protection for structural steel, wood, bulkheads, and upgrades the fire resistance of existing concrete. Other areas of application include refineries, petrochemical, pharmaceutical facilities, pulp and paper mills, offshore platforms, nuclear and conventional power plants, factories, warehouses, institutional and biomedical facilities.APPLICATION AREAS

U-STUCCO™ FRX can be used both in new construction and renovation projects. It can be applied in a single pass of up to 1” (or less) to nearly any substrate, including plywood, OSB, CMU blocks, concrete, metal, AAC, EPS, XPS and ICF systemsAPPLICATION METHODS

Apply by hand trowel or plaster gun. APPLICATION TEMPERATURE

Ambient and surface temperature must be between +40°F (+5°C) and +95°F (+35°C). Try avoiding application under extreme wind, cold or direct sunlight conditions or when temperatures may fall outside this range within 24 hours of application. Provide supplemental heat and protection from precipitation as needed. SURFACE PREPARATION

GENERAL : Before applying U-STUCCO™ FRX, the substrate or coating must be free of all oil, grease, condensation, or other contamination.STEEL : If primer is required, steel prearation before priming should be done in accordance with the recommended primer’s product data sheet. Contact U-STUCCO™ USA Technical Support for approved primers.GALVANIZED STEEL : U-STUCCO™ FRX can be applied directly over galvanized surface. If priming is required, contact U-STUCCO™ USA Technical Support for recommendations.NON-FERROUS METALS : Aluminum, copper and other non-ferrous metals shall be primed with one coat of U-STUCCO™ PRXCONCRETE & MASONRY : Thoroughly dampen concrete and masonry substrate if necessary before applying U-STUCCO™ FRX

For application to very dense or smooth concrete and additional surface preparation options, contact U-STUCCO™ USA Technical Support.

MIXING

Pour U-STUCCO™ FRX 35,2 lb (16 kg) bag into a mixing container, followed by 4.7 to 5.0 gallons (18 to 19 lt) of cool, clean potable water (let hose run to clear it of hot water) and mix for approximately for 12 minutes. For the mixing process, a hand mixer or plastering machine can be used. Mixing should be done mechanically at a high speed until the mixture reaches a homogenous consistency and workability.Only U-STUCCO™ USA approved additives can be added to this product.

APPLICATION

Apply by trowel or plaster gun to a minimum thickness of approximately ½ inch (12 mm) On lathed construction the total thickness can be up to 2 inches (50 mm) Using a trowel or plaster pump, apply U-STUCCO™ FRX to the properly prepared surface. Always float the material uniformly to provide a surface receptive to the application of the finish coat. Various finishes can be achieved with different techniques.

Read the entire label before using this product. All materials are to be installed in compliance with local building code requirements, ASTM C926, C1063 and U-STUCCO™ USA’s specifications. All materials are to be installed in compliance with local building code requirements, ASTM C926, C1063 and U-STUCCO’s specifications.

APPLICATION THICKNESS

The minimum thickness over any substrate is ½ inch (12 mm). Some assemblies may require specific minimum thickness.

U-STUCCO™ FRX can be applied up to 1 inch (25 mm) thickness with a single pass.CURING

Curing time (4 to 8 hours) may vary due to ambient temperature, surface temperature, surface porosity, application methods, and thickness of material. All freshly applied material must be protected by an approved protective system from inclement weather until fully dry.WORKING TIME

Sets in 90 to 120 minutes after mixing, depending on temperature, humidity and substrate conditions. COVERAGE

Approximate Coverage, depending on the condition of substrate and the thickness of application is based on uniform thickness and zero waste factor. 35.2 lb (16 kg) bag of U-STUCCO™ XPX will cover approximately; 1/4” : 68 sq ft

1/2'“ : 34 sq ft

3/4” : 23 sq ft

1” : 17 sq ft

Coverage may vary due to ambient temperature, surface temperature, surface porosity, mixing methods, application methods, amount of water, wall type and metal lath type. Coverage must be verified in the field using the same procedures and conditions that will be present at the project.

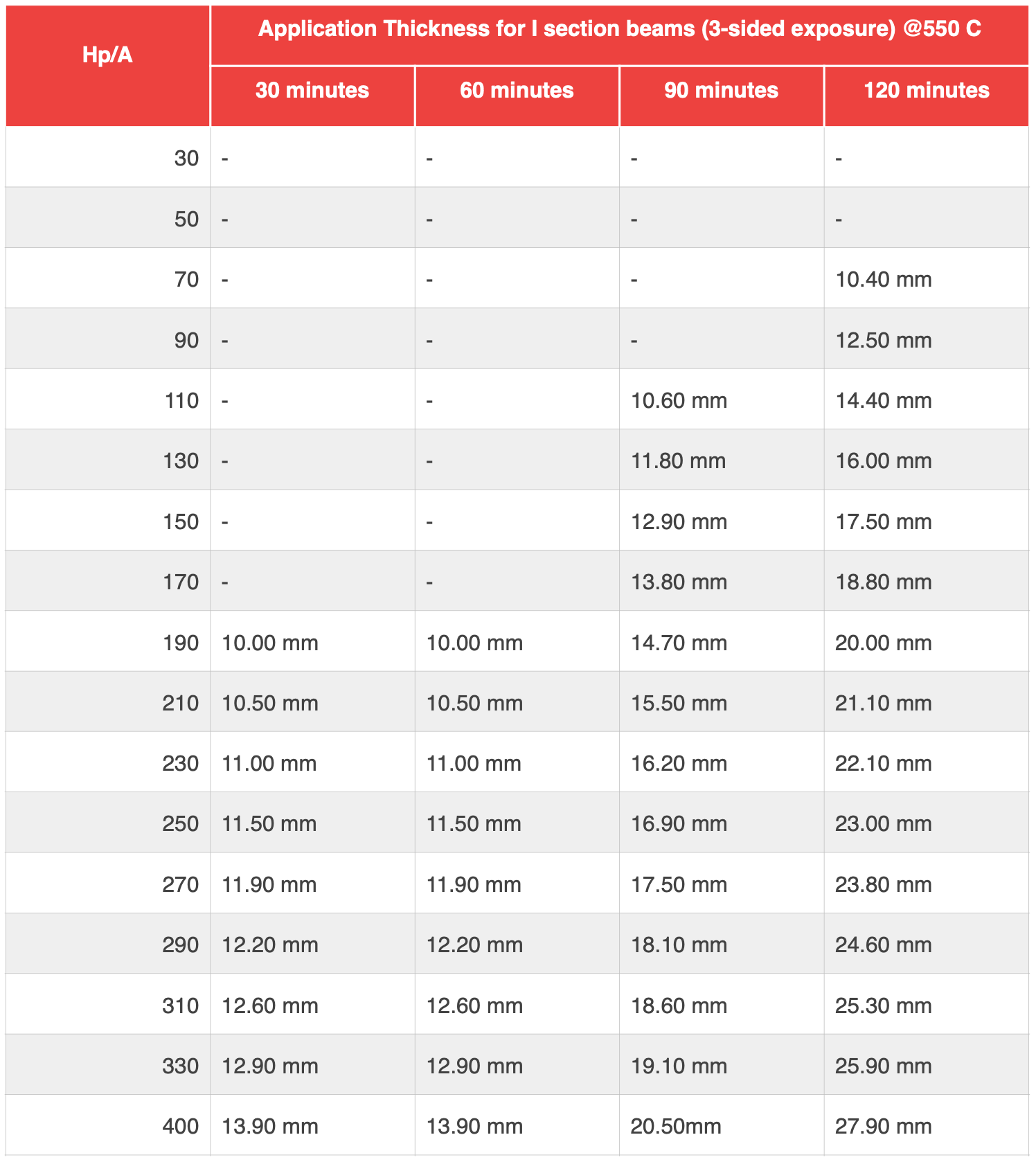

FIRE PROTECTION THICKNESS (AS 1530) : I SECTION BEAMS (3-SIDED EXPOSURE)

FIRE PROTECTION THICKNESS (AS 1530) : H SECTION COLUMNS (4-SIDED EXPOSURE)

PACKAGING AND STORAGE

Available in 35.2 lb (16 kg) net weight in a multi-layer moisture resistant bag. Store off ground and protect from rain and moisture. Storage space temperature should be no lower than +40°F (+5°C) HEALTH AND SAFETY

It may be irritant to eyes and skin when exposed. Wear appropriate dust, skin and eye protection. In case of eye contact, flush immediately with water and consult a physician. Wash hands with soap and water after use. Keep out of reach of children. For more information on handling this product refer to its material safety data sheet (SDS). QUALITY MANAGEMENT

U-STUCCO™ Green Building Materials are produced under ISO 9001:2008 quality standards. The product quality is monitored according to the EN 998-1 by U-STUCCO™ USA, LLC in the factory laboratories. LIMITED WARRANTY

U-STUCCO™ FRX is warranted to perform in accordance with the product specification when used pursuant to the application instructions. This warranty is limited to and shall not exceed the total amount paid by the buyer for the product here under. In no event U-STUCCO™ USA, LLC shall be liable for any loss of profits, special or consequential damages in respect to any claim. The foregoing warranties are in lieu of all other warranties express or implied including those concerning suitability for a particular use. This product data sheet has been prepared in good faith on the basis of information available at the time of publication. It is intended to provide users with information about the guidelines for the proper use and application of the covered product(s) under normal environmental and working conditions. Because each project is different, U-STUCCO™ USA, LLC cannot be responsible for the consequences of variations in such conditions, or for unforeseen conditions. IMPORTANT NOTICE TO USER

This information is designed to guide you and has been conscientiously compiled according to the latest state of our technology. U-STUCCO™ USA assumes no liability, expressed or implied, in connection with the use of the product because of the great variety of applications and working conditions.